Safety stock mitigates the impact of supplier interruptions and lead time uncertainty and keeps the supply chain moving until the disruption passes or the company has found a new supplier.īeyond keeping each step of the supply chain running smoothly, safety stock also cuts down on time spent on communication, paperwork and warehouse duties. These interruptions have far-reaching impacts on the rest of the supply chain, including delaying the completion of other product components, derailing customer delivery schedules or causing retail disruptions. Unexpected disruptions on the supplier side, such as raw material shortages, production issues, legislative or political measures and operational shutdowns, can have a major impact on your inventory levels.

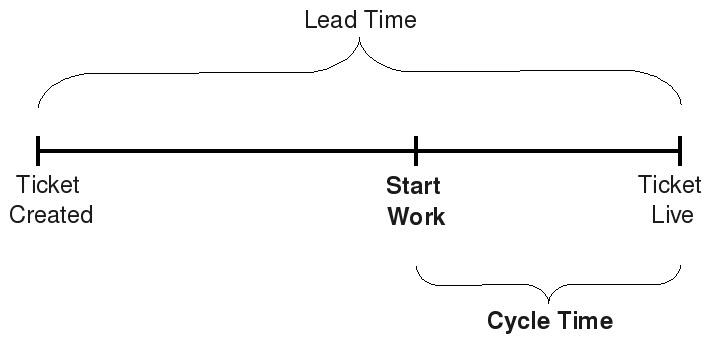

That process can take days, or even weeks, making safety stock an invaluable bridge that keeps the business running while resolving the stockout. Safety stock can help companies reduce the risk of completely running out of a certain product and prevent operations from coming to a halt while the business locates, purchases and delivers this inventory. Safety stock gives companies enough breathing room to replenish stock while meeting this increased demand. Many factors can influence spikes in demand, including seasonal impacts, sudden shifts in customer trends, panic buying or a competitor's departure. 10 Reasons to Keep Safety Stockįluctuations in demand are among the primary reasons to maintain safety stock. Below are many of the biggest reasons to have this extra inventory. There are several reasons businesses should have safety stock on hand, and it can quickly prove its value when the unexpected strikes. Stockouts result in $984 billion worth of lost sales worldwide, with North American companies alone losing $144.9 billion, according to a study by IHL Group. Running out of stock is an expensive issue for businesses across the globe. Tracking current stock levels accurately while considering present and future market conditions and accounting for supply lead times is just the start of effective inventory control.Įxcellent inventory management requires coordinating cycle stock and safety stock to ensure that inventory levels stay in line with demand and supply, making inventory management straightforward and more consistent. How Can Safety Stock Improve Inventory Management?Įffective inventory management relies on the cushion that safety stock provides. Safety stock mitigates the risks and consequences of stockouts, allowing your supply chain to proceed as usual even after cycle stock runs out. Inaccurate demand or inventory forecasts.Safety stock acts as a buffer amount that accounts for uncertainties such as: Stock inventory usually consists of cycle stocks, or the inventory that is expected to be sold within a given period, and safety stock. However, there are some essential guidelines that operational decision-makers need to understand to optimize safety stock in a way that supports overall business objectives.

#LEAD TIME CALC HOW TO#

Learning how to calculate safety stock and keeping adequate amounts on hand ensures that the supply chain runs smoothly despite stocking delays and temporary outages. Running low on stock is an inevitability, but it doesn't have to disrupt business.

Stockouts also reduce the supply chain's overall efficiency. Revenue lost from stockouts is often coupled with the loss of customers who find the items elsewhere and often never return to the business. East, Nordics and Other Regions (opens in new tab)

0 kommentar(er)

0 kommentar(er)